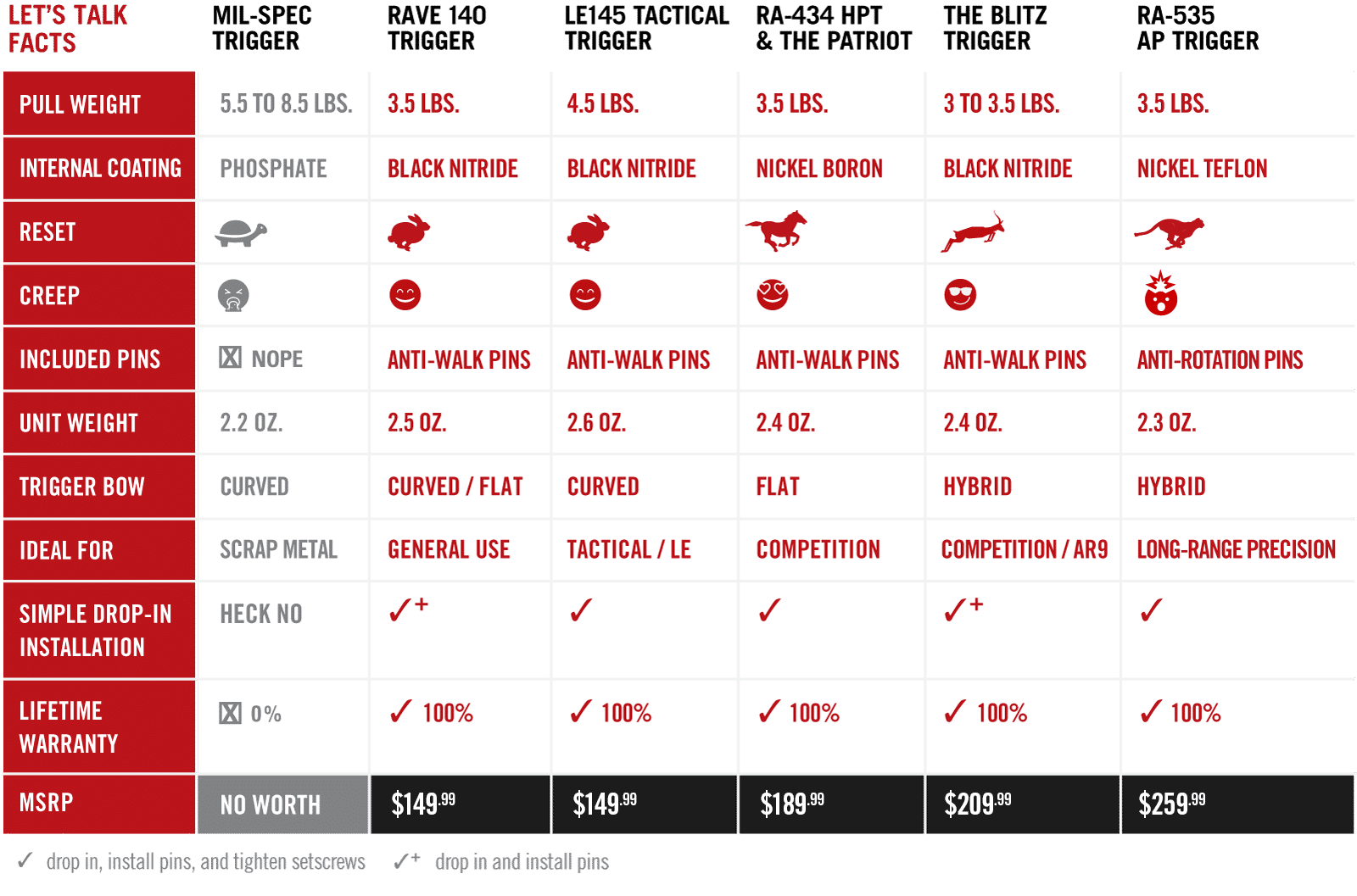

RISE Trigger Comparison Chart

RISE Drop-in Triggers

All RISE single-stage drop-in triggers have a telltale, short reset; no take-up; and are contained in easy-to-install 6061 aerospace aluminum housings. The triggers are precision machined at RISE’s headquarters in Broken Arrow, Oklahoma. Internal craftsmen assemble and check each trigger for accurate pull weight and the crisp operation RISE customers expect and love. Here’s a trigger comparison to make your decision a little easier.

| LET’S TALK FACTS | MIL-SPEC TRIGGER | RAVE 140 TRIGGER | LE145 TACTICAL TRIGGER | RA-434 HPT & THE PATRIOT | THE BLITZ TRIGGER | RA-535 APT TRIGGER |

|---|---|---|---|---|---|---|

| PULL WEIGHT | 5.5 TO 8.5 LBS. | 3.5 LBS. | 4.5 LBS. | 3.5 LBS. | 3 TO 3.5 LBS. | 3.5 LBS. |

| INTERNAL COATING | PHOSPHATE | BLACK NITRIDE | BLACK NITRIDE | NICKEL BORON | BLACK NITRIDE | NICKEL TEFLON |

| RESET | ||||||

| CREEP | ||||||

| INCLUDED PINS | NOPE | ANTI-WALK PINS | ANTI-WALK PINS | ANTI-WALK PINS | ANTI-WALK PINS | ANTI-ROTATION PINS |

| UNIT WEIGHT | 2.2 OZ. | 2.5 OZ. | 2.6 OZ. | 2.4 OZ. | 2.4 OZ. | 2.3 OZ. |

| TRIGGER BOW | CURVED | CURVED / FLAT | CURVED | FLAT | HYBRID | HYBRID |

| IDEAL FOR | SCRAP METAL | GENERAL USE | TACTICAL / LE | COMPETITION | COMPETITION / AR9 | LONG-RANGE PRECISION / COMPETITION |

| SIMPLE DROP-IN INSTALLATION | HECK NO | |||||

| LIFETIME WARRANTY | 0% | |||||

| MSRP | NO WORTH | $149.99 | $149.99 | $189.99 | $209.99 | $259.99 |

| PURCHASE | THROW IN GARBAGE | BUY HERE | BUY HERE |

![]() drop in, install pins, and tighten setscrews

drop in, install pins, and tighten setscrews ![]() drop in and install pins

drop in and install pins

What’s on the inside?

RISE precision machines the drop-in triggers’ internal components from S7 tool steel then heat treats them for heavy-hit hardness. This enables the triggers to deliver solid contact with the firing pin time after time. Next, RISE finishes the trigger parts with one of three metal treatments.

Black Nitride is a surface treatment that yields a smooth, uniform, and corrosion-resistant finish. It improves the durability, increases hardness and strength, and is easy to clean.

Nickel Boron coating provides an additional layer of hardness and strength to the steel while reducing contact points between parts’ surfaces. It acts almost as a lubricant, providing smooth operation of the trigger.

Nickel Teflon is an advanced finish with Teflon chips mixed in the nickel prior to application. It provides a harder, stronger surface and slick, smooth operation. Because the Teflon chips are incorporated in the nickel, Teflon continues to surface over time, enhancing the lubricity and feel with use.